Top 5 Tips for Mastering Your Manual Lathe Machine

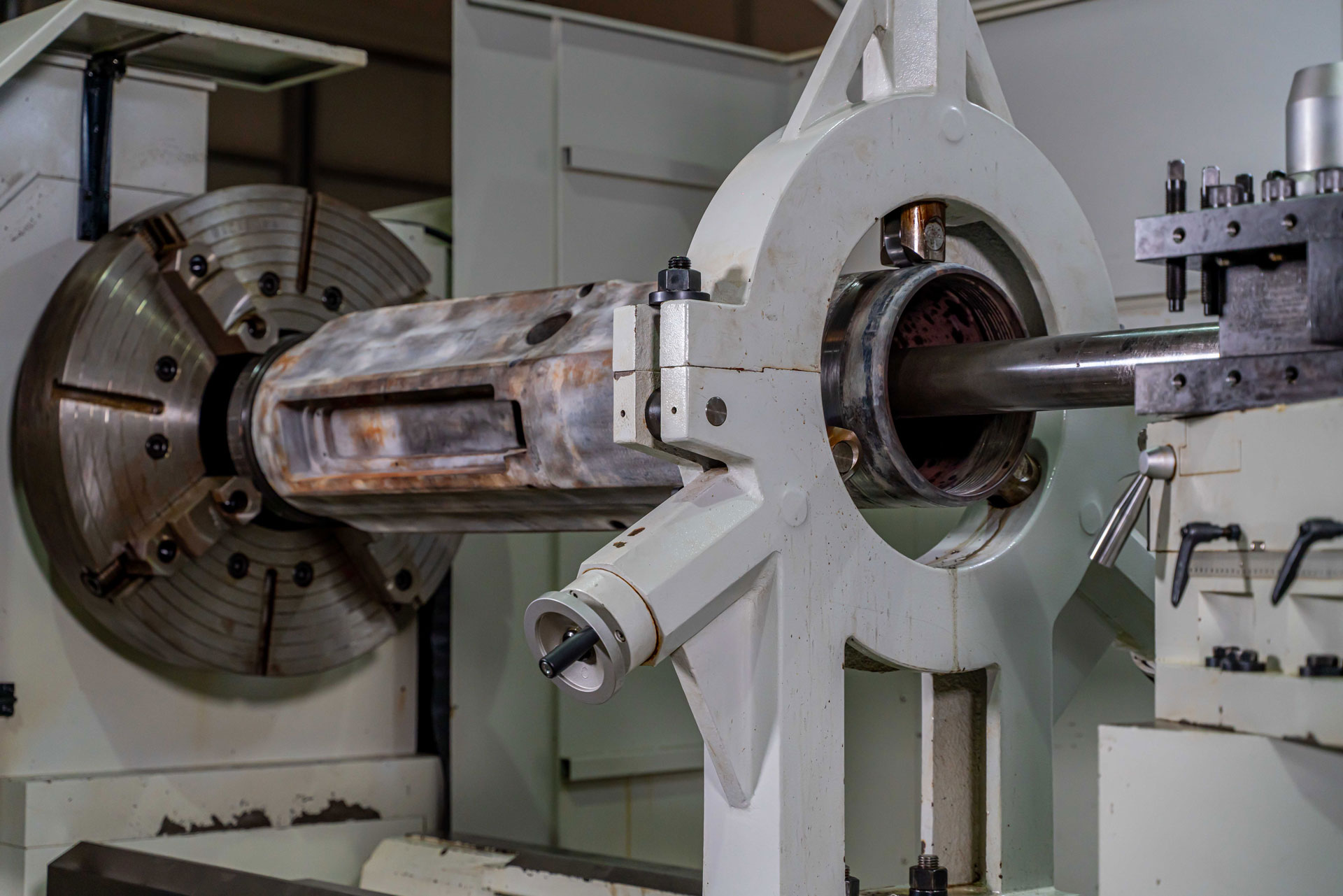

A manual lathe machine is a versatile and essential tool used in workshops for shaping and cutting materials such as metal, wood, and plastic. It works by rotating the workpiece against a stationary cutting tool to remove material, allowing for precise shaping, drilling, and finishing. Manual lathes are operated by hand, giving users full control over the cutting process.

A manual lathe machine is a powerful tool used for shaping and cutting materials like metal, wood, and plastic. It plays a crucial role in workshops, offering precise control over the cutting process. Whether you're a hobbyist just starting out or a professional looking to sharpen your skills, mastering the manual lathe machine is essential for creating high-quality, accurate parts. In this blog, we will cover the top 5 tips that will help you master your manual lathe machine, ensuring that you work safely and efficiently while achieving the best results.

Tip 1: Understand the Basics of Your Manual Lathe Machine

Before diving into complex projects, it’s important to get comfortable with the basic parts and functions of the manual lathe machine. A manual lathe has several key components, including the headstock, tailstock, carriage, tool post, and cross slide. Knowing what each part does and how they work together will make your job much easier.

Note - Looking to enhance your workshop with a high-quality Manual Lathe Machine? Raysun Techno Industries LLC offers a range of reliable and precision-engineered manual lathe machines to suit all your machining needs. Contact Raysun Techno Industries LLC today to explore the best options for your business and experience superior craftsmanship and performance.

Key Components to Know:

- Headstock: This is where the motor and the drive system are located. The headstock holds the main spindle, which rotates the workpiece.

- Tailstock: The tailstock supports the other end of the workpiece and can hold tools like drills or reamers.

- Carriage: This part moves the cutting tool along the workpiece.

- Cross Slide: The cross slide is used to adjust the position of the tool, allowing for precise cuts.

Having a clear understanding of these components will allow you to operate your lathe with greater confidence. It’s also a good idea to read the machine’s manual thoroughly to familiarize yourself with its specific functions and settings.

Tip 2: Always Prioritize Safety

Safety should always come first when using a manual lathe machine. Lathes involve high-speed rotating parts, and working with them can be dangerous if safety procedures are not followed. Ensuring your safety will help you avoid accidents and injuries while allowing you to work with focus and precision.

Safety Precautions:

- Wear Proper Protective Gear: Always wear safety glasses, gloves, and protective clothing to safeguard yourself from flying debris and chips.

- Check the Machine Before Use: Before starting the lathe, ensure that all parts are securely tightened, and check for any loose or damaged components.

- Keep Your Workspace Clean: Make sure the work area is free of clutter, as any small items could be dangerous when the machine is in operation.

- Never Rush the Process: Operating a lathe machine requires patience and focus. Never attempt to rush through tasks, as this can lead to accidents.

When you prioritize safety, you create a better working environment and reduce the chances of mistakes or injuries, allowing you to focus on perfecting your skills.

Tip 3: Practice Proper Tool Setup and Adjustment

One of the keys to achieving high-quality results with your manual lathe machine is setting up the tools properly. Whether you’re cutting, shaping, or sanding, your lathe tools must be positioned correctly to make accurate cuts. Improper tool setup can lead to poor results, wasted material, and even damage to the machine.

Tool Setup Tips:

- Ensure Correct Tool Positioning: The cutting tool should be aligned with the center of the workpiece to avoid uneven cuts. Make sure the tool is secure in the tool post and properly aligned before beginning.

- Adjust Cutting Speed: Different materials require different cutting speeds. Always adjust the speed of the lathe based on the material you're working with. For example, softer metals may require slower speeds, while harder materials may require faster speeds.

- Select the Right Cutting Tool: There are various types of lathe tools for different operations. Choose the right tool for the task—whether it's a turning tool, parting tool, or facing tool. Using the wrong tool can lead to poor results or damage to both the workpiece and the machine.

Once you've set up your tools correctly, test them on a small piece of scrap material to make sure they are performing as expected. This helps avoid mistakes and ensures the correct settings for your project.

Tip 4: Focus on Precision and Measurement

Precision is critical when working with a manual lathe machine. Achieving accurate measurements and maintaining a high level of precision can make the difference between a successful project and a failure. Even small mistakes can lead to parts that don't fit properly or meet specifications.

How to Improve Precision:

- Use a Caliper or Micrometer: Invest in a high-quality caliper or micrometer to measure your workpiece. Regularly check the dimensions to ensure you're staying within your desired tolerance.

- Take Small Cuts: When turning or shaping a workpiece, take small cuts rather than attempting to remove too much material at once. This not only improves precision but also reduces the risk of damaging the workpiece.

- Double-Check Measurements: Always double-check measurements before making cuts. Take the time to measure multiple times, especially when working on critical parts.

- Use a Center Finder: A center finder tool helps you locate the exact center of the workpiece, ensuring that the lathe tool is properly aligned for precise cuts.

By focusing on precision, you ensure that your work is accurate, professional, and ready for use. Precision is key for creating high-quality parts and avoiding mistakes that could be costly in both time and materials.

Tip 5: Keep Your Lathe Machine Maintained

Like any piece of machinery, your manual lathe machine requires regular maintenance to keep it running smoothly. Proper maintenance ensures that the machine operates efficiently, prolongs its lifespan, and reduces the likelihood of malfunctions. A well-maintained lathe is also safer to use.

Maintenance Tips:

- Lubricate Moving Parts: Regularly lubricate the lathe’s moving parts, such as the carriage and cross slide. This reduces friction and wear, ensuring smooth operation.

- Clean the Lathe After Each Use: After every use, clean the lathe to remove any metal chips, dust, and debris. This helps prevent buildup and keeps the machine in top condition.

- Check for Wear and Tear: Inspect the machine regularly for any signs of damage or wear. Pay attention to parts like the spindle and tool post, as these can wear out over time.

- Calibrate the Machine: Occasionally, recalibrate the machine to ensure that it is cutting accurately. This is especially important if you notice a drop in precision or performance.

Proper maintenance not only helps the machine last longer but also ensures it operates at peak performance. A well-maintained lathe will provide more consistent results and reduce the chance of breakdowns.

Conclusion

Mastering your manual lathe machine takes time, patience, and attention to detail. By understanding the machine's components, prioritizing safety, setting up your tools correctly, focusing on precision, and maintaining your machine, you can ensure that your lathe works efficiently and safely. These tips will help you create high-quality, precise parts while improving your skills and confidence with the machine.

Whether you’re just starting with a manual lathe machine or have been using one for years, following these tips will take your work to the next level. With practice and the right techniques, you’ll be able to produce professional-grade pieces and become a true expert in lathe machining.

For more insightful articles related to this topic, feel free to visit biplosangeles.com

What's Your Reaction?